Discover the power of resealable ziplock bags for your business! From protecting products to enhancing branding, these versatile bags offer many advantages.

Do you ever wonder why so many successful businesses choose to package their products in resealable ziplock bags? As a business owner, it’s essential for you to find the perfect packaging solution that not only protects your products but also presents them in the best possible way. This is where resealable ziplock bags come in. Labeled as the “ultimate packaging solution,” these bags offer a multitude of benefits that make them top choices for businesses. Let’s explore some of the advantages of using resealable ziplock bags for your business.

Protect and Preserve Your Products

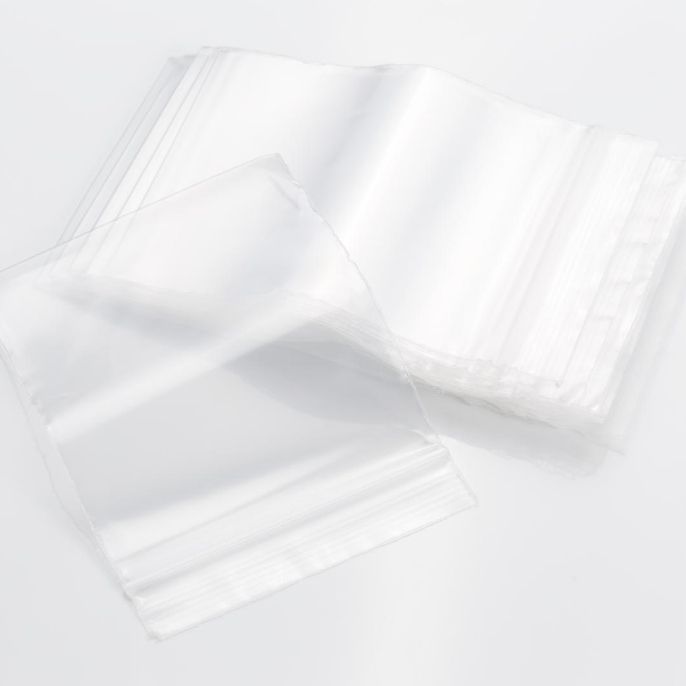

Resealable ziplock bags provide an excellent means of protecting and preserving your products. Their secure and airtight seal maintains the freshness of your goods, safeguarding them from moisture, dirt, and other contaminants. This means your products will retain their shelf life, appearance, aroma, and taste for an extended period. Consequently, both you and your customers can feel confident knowing that the items you provide stay protected.

Versatility in Use

Resealable ziplock bags aren’t just for packaging food or small items. You can use them for a wide range of products, making them highly versatile. From storing cosmetics and toiletries to organizing office supplies or even packing travel essentials, resealable ziplock bags offer endless possibilities. This versatility makes them an excellent investment for businesses looking for a multipurpose packaging solution. With sizes at Royal Bag ranging from 1/2 x 1/2” to 28 x 30”, as well as thicknesses from 2 mil to 6 mil, there is a solution for every business owner. No matter what type of product you sell, resealable ziplock bags can offer the protection and convenience your customers are looking for.

Customization and Branding Opportunities

When it comes to packaging, standing out from the competition is essential. That’s where Royal Bag steps in. We offer a wide range of custom bag options for your business, allowing you to create packaging uniquely tailored to your brand. Whether you want to print your logo and tagline or incorporate your brand colors, the possibilities are endless.

Choosing Royal Bag for your resealable ziplock bags showcases your company’s commitment to providing exceptional products, strengthens your brand identity, and fosters customer loyalty. Customized packaging creates a memorable experience that keeps buyers coming back for more of what you have to offer.

As you can see, resealable ziplock bags provide numerous advantages to businesses in various industries. To maximize these benefits, it’s essential to invest in high-quality bags that will stand the test of time. That’s where Royal Bag comes in, offering an assortment of ziplock bags wholesale for your business.

At Royal Bag, we understand the importance of delivering durable, reliable, and effective packaging solutions tailored to the unique needs of your business. Partnering with us ensures that you benefit from our vast selection of high-quality resealable ziplock bags at competitive wholesale prices. Don’t miss out on an opportunity to improve your business operations in a meaningful way. Contact us today to learn more about our ziplock bag options!