If you’re the owner of a successful business, chances are you didn’t reach that level of success by selling only one type of product. In fact, as your business grows, it’s only natural that you’re going to expand existing product lines and even create new items to experiment with. As such, it’s critical that you have the materials to properly ship each of your products—no matter how they’re shaped or what their size is. Fortunately, poly bags are perfect for this very purpose. Made with flexible and strong materials, each bag is designed to secure the item inside and keep it protected throughout the stressful shipping process. All you need to decide is which type of bag best fulfills your needs. Read on to learn the types of poly bags for packaging and which products they can be most effectively used for.

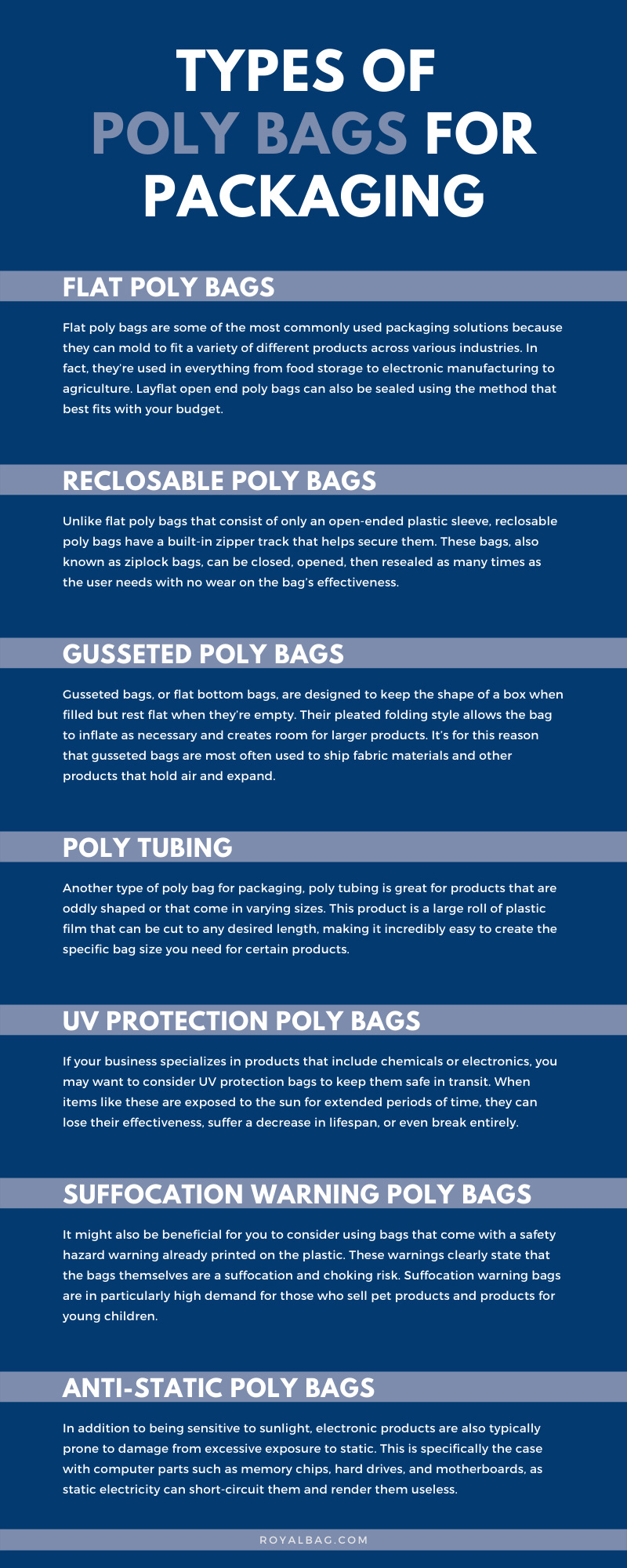

Flat Poly Bags

Flat poly bags are some of the most commonly used packaging solutions because they can mold to fit a variety of different products across various industries. In fact, they’re used in everything from food storage to electronic manufacturing to agriculture. Layflat open end poly bags can also be sealed using the method that best fits with your budget. Rather than requiring you to purchase specific equipment to properly secure these bags, you have your choice of heat sealing, tying, stapling, or even taping them closed. This way, you can use them in whatever packaging process you’ve already established in your business.

Reclosable Poly Bags

Unlike flat poly bags that consist of only an open-ended plastic sleeve, reclosable poly bags have a built-in zipper track that helps secure them. These bags, also known as ziplock bags, can be closed, opened, then resealed as many times as the user needs with no wear on the bag’s effectiveness. Oftentimes, products that arrive unassembled will have smaller building utensils—such as screws and nails—stored in these bags. This not only ensures that all parts of the item are secured, but that everything is organized and present upon arrival to a customer’s door. Larger reclosable bags are also commonly used in the manufacturing process to keep track of any small parts and tools that require later use.

Gusseted Poly Bags

Gusseted bags, or flat bottom bags, are designed to keep the shape of a box when filled but rest flat when they’re empty. Their pleated folding style allows the bag to inflate as necessary and creates room for larger products. It’s for this reason that gusseted bags are most often used to ship fabric materials and other products that hold air and expand. Since they’re traditionally open on one side, like flat poly bags, they can also be sealed in a multitude of ways. This makes them a very important item for those wanting to ship larger materials in an airtight package.

Poly Tubing

Another type of poly bag for packaging, poly tubing is great for products that are oddly shaped or that come in varying sizes. This product is a large roll of plastic film that can be cut to any desired length, making it incredibly easy to create the specific bag size you need for certain products. Because these bags can be cut to any size, they’re generally open on two ends and will need to be sealed on both sides before shipping. It’s also important to note that if you want bags that are uniform, it’s often easier to order bags that are made to those specifications rather than cutting them yourself. However, for uniquely shaped products that you don’t normally ship, poly tubing is the most effective method.

UV Protection Poly Bags

If your business specializes in products that include chemicals or electronics, you may want to consider UV protection bags to keep them safe in transit. When items like these are exposed to the sun for extended periods of time, they can lose their effectiveness, suffer a decrease in lifespan, or even break entirely. This can affect your overall client satisfaction rate and, if you’re not careful, your sales. So it’s often best to play it safe by packaging your more sensitive products in these tinted UV protection bags. These bags also contain a thicker layer of plastic that helps better protect items from other elements such as water and dirt.

Suffocation Warning Poly Bags

It might also be beneficial for you to consider using bags that come with a safety hazard warning already printed on the plastic. These warnings clearly state that the bags themselves are a suffocation and choking risk. Suffocation warning bags are in particularly high demand for those who sell pet products and products for young children. This shows that you’re looking out for your customers’ best interests and keeping them informed of the potential dangers that come with unwrapping the product.

Anti-Static Poly Bags

In addition to being sensitive to sunlight, electronic products are also typically prone to damage from excessive exposure to static. This is specifically the case with computer parts such as memory chips, hard drives, and motherboards, as static electricity can short-circuit them and render them useless. It’s for this reason that many technology suppliers ship these materials in anti-static bags to protect them. Infused with a special additive that stops static from gathering on its surface, these bags negate static entirely to keep it from ruining the product. Anti-static bags are also specially dyed a unique color to make them easily identifiable for both you and those delivering the item.

For all your product packaging needs, reach out to us at Royal Bag and ask us about our extensive inventory. Along with these different product bagging options, we also offer custom poly bags to best ensure that all your products have the proper shipment materials. These bags can be specifically sized and labeled to match your product, and they also come with a series of potential features for you to choose from. In addition, for those who use large quantities of specific poly bags, we also sell all these bags on rolls to give you the best-value deal.